Our soil remediation activities An innovative and personalized service

At VALGO, we leverage the expertise of our teams and the advanced capabilities of our R&D laboratory to design tailor-made solutions adapted to the most complex problems.

Our comprehensive approach combines cutting-edge technologies and precise soil analysis, promoting land use:

- Bioremediation: stimulating microorganisms to biodegrade organic pollutants

- Thermal desorption: removal of pollutants (hydrocarbons, chlorinated solvents, mercury) by volatilization using a heat source

- Chemical treatment: treatment of pollutants by injection of oxidizing or reducing agents

- Pumping and treatment: purification of contaminated groundwater

- Stabilization and solidification: applied geotechnical techniques enabling the trapping of pollutants through the addition of an additive to prevent their dispersion

Our added value

Innovation

VALGO has an internal laboratory to support its field operations: testing, technical validations, deployment support, controls.

The integrated R&D department conducts internal research projects or projects in partnership with academic laboratories or industrial stakeholders, aiming to expand the company’s portfolio of technologies, enhance the efficiency of existing processes, broaden the range of pollutants that can be addressed, or improve the monitoring and traceability of operations.

In-situ treatment as a differentiation axis

Thermal desorption has been a major advancement in the in-situ treatment of pollution. This technique is a core competency of VALGO’s teams and continues to be refined with each new application. It allows for the treatment of a wide range of pollutants, including those with low mobility, resulting in low residual concentrations. It also accelerates the extraction kinetics of pollutants in more conventional techniques such as venting.

Taking into account emerging pollutants

Numerous research and development projects focus on new polluting compounds, aiming to resolve scientific uncertainties about their behavior and the technological challenges of treatment. One of VALGO’s major research advances concerns the development of a patented technology for extracting PFAS, perfluoroalkyl and polyfluoroalkyl substances known for their persistence in the environment. However, the pollutants addressed by R&D are numerous: the treatment of groundwater contaminated by lithium, heterocyclic compounds, or nitrogen compounds; the treatment of phthalates; and the management of microplastics.

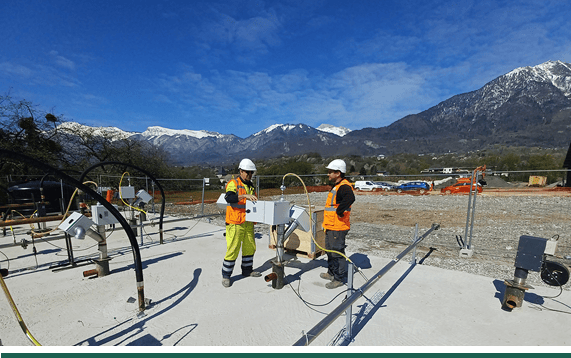

A constant requirement in terms ofsafety and environmental quality

Our remediation operations are governed by a demanding QHSE policy. Certifications, controls, traceability and continuous training: each project is carried out in compliance with the strictest standards to protect people, property and the environment.

MASE certification

VALGO is MASE certified (Manual for Improving Safety, Health and Environment): a recognized guarantee of reliability in high-risk industrial environments. This certification attests to our rigorous approach to personnel safety and risk prevention on construction sites.

A vision focused on the circular economy

The objective of developing these in situ solutions and the treatment of complex pollutants aims to ultimately enable the recovery of materials.

Continuing training of teams

Training is one of the cornerstones of our strategy. Our operators hold all the necessary certifications for working in industrial environments. They also benefit from a continuous training and feedback program that allows them to master techniques in complex settings.